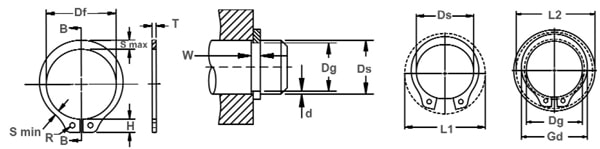

| RING NO. | SHAFT DIAMETER | GROOVE SIZE | RING SIZE & WEIGHT | CLEARANCE DIA. | i THRUST LD (kN) Sqr. corner abutment | ||||||||||||

| DIAMETER | WIDTH | DEPTH | FREE DIAMETER | THICKNESS *** | wt. Per 1000 pcs. | Ex- panded over Shaft | Re- leased in Groove | ||||||||||

| Ring (Safety Factor of 4) | Groove (Safety Factor of 2) | ||||||||||||||||

| Ds mm | Ds INCH | ||||||||||||||||

| Dq | to I | F.I.M.** | W | 101 | d | Df | tol | T | tol | kg | L1 | L2 | Pr | Pg | |||

| MSH-4* | 4 | 0.157 | 3.80 | -0.08 | 0.03 | 0.32 | + 0.05 | 0.10 | 3.60 | +0.05 -0.10 | 0.25 | ±0.05 | 0.017 | 7.0 | 6.8 | 0.6 | 0.2 |

| MSH-5* | 5 | 0.197 | 4.75 | 0.03 | 0.50 | + 0.10 | 0.13 | 4.55 | 0.40 | ±0.06 | 0.029 | 8.2 | 7.9 | 1.1 | 0.3 | ||

| MSH-6* | 6 | 0.236 | 5.70 | 0.03 | 0.50 | 0.15 | 5.45 | 0.40 | 0.040 | 9.1 | 8.8 | 1.4 | 0.4 | ||||

| MSH-7 | 7 | 0.275 | 6.60 | -0.10 | 0.05 | 0.70 | + 0.15 | 0.20 | 6.35 | +0.05 -0.15 | 0.60 | 0.10 | 12.3 | 11.8 | 2.6 | 0.7 | |

| MSH-6 | 8 | 0.315 | 7.50 | 0.05 | 0.70 | 0.25 | 7.15 | 0.60 | 0.12 | 13.6 | 13.0 | 3.1 | 1.0 | ||||

| MSH-9 | 9 | 0.354 | 8.45 | 0.05 | 0.70 | 0.28 | 8.15 | 0.60 | 0.15 | 14.5 | 13.8 | 3.5 | 1.2 | ||||

| MSH-10 | 10 | 0.393 | 9.40 | 0.05 | 0.70 | 0.30 | 9.00 | 0.60 | 0.19 | 15.5 | 14.7 | 3.9 | 1.5 | ||||

| MSH-11 | 11 | 0.433 | 10.35 | -0.12 | 0.05 | 0.70 | 0.33 | 10.00 | 0.60 | 0.23 | 16.4 | 15.6 | 4.3 | 1.8 | |||

| MSH-12 | 12 | 0.472 | 11.35 | 0.05 | 0.70 | 0.33 | 10.85 | 0.60 | 0.24 | 17.4 | 16.6 | 4.7 | 2.0 | ||||

| MSH-13 | 13 | 0.512 | 12.30 | 0.10 | 1 00 | 0.35 | 11.90 | +0.15 -0.25 | 0.90 | 0.44 | 19.7 | 18.8 | 7.5 | 2.2 | |||

| MSH-14 | 14 | 0.551 | 13 25 | 0.10 | 1 00 | 0.38 | 12 90 | 0.90 | 0.49 | 20.7 | 19.7 | 8.1 | 2.6 | ||||

| MSH-15 | 15 | 0.591 | 14.15 | 0.10 | 1 00 | 0.43 | 13.80 | 0.90 | 0.54 | 21.7 | 20.6 | 8.7 | 3.2 | ||||

| MSH-16 | 16 | 0.630 | 15.10 | -0.15 | 0.10 | 1.00 | 0.45 | 14.70 | 0.90 | 0.59 | 22.7 | 21.6 | 9.3 | 3.5 | |||

| MSH-17 | 17 | 0.669 | 16.10 | 0.10 | 1.00 | 0.45 | 15.75 | 0.90 | 0.64 | 23.7 | 22.6 | 9.9 | 4.0 | ||||

| MSH-18 | 18 | 0.708 | 17.00 | 0.10 | 1.20 | 0.50 | 16.65 | 1.10 | 0.92 | 26.2 | 25.0 | 16.0 | 4.4 | ||||

| MSH-19 | 19 | 0.748 | 17.95 | 0.10 | 1.20 | 0.53 | 17.60 | 1.10 | 0.95 | 27.2 | 25.9 | 16.9 | 4.9 | ||||

| MSH-20 | 20 | 0.787 | 18.85 | 0.10 | 1.20 | 0.58 | 18.35 | 1.10 | 1.0 | 28.2 | 26.8 | 17.8 | 5.7 | ||||

| MS H-21 | 21 | 0.826 | 19.80 | 0.10 | 1.20 | 0.60 | 19.40 | 1.10 | 1.1 | 29.2 | 27.7 | 18.6 | 6.2 | ||||

| MSH-22 | 22 | 0.866 | 20.70 | 0.10 | 1.20 | 0.65 | 20.30 | 1.10 | 1.3 | 30.3 | 28.7 | 19.6 | 7.0 | ||||

| MSH-23 | 23 | 0.905 | 21.65 | 0.10 | 1.20 | 0.67 | 21.25 | 1.10 | 1.4 | 31.3 | 29.6 | 20.5 | 7.6 | ||||

| MSH-24 | 24 | 0.945 | 22.60 | 0.10 | 1.20 | 0.70 | 22.20 | 1.10 | 1.5 | 34.1 | 32.4 | 21.4 | 8.2 | ||||

| MSH-25 | 25 | 0.984 | 23.50 | 0.10 | 1.20 | 0.75 | 23.10 | 1.10 | 1.6 | 35.1 | 33.3 | 22.3 | 9.2 | ||||

| MSH-26 | 26 | 1.023 | 24.50 | 0.10 | 1.20 | 0.75 | 24.05 | 1.10 | 1.8 | 36.Q | 34.2 | 23.2 | 9.6 | ||||

| MSH-27 | 27 | 1.063 | 25.45 | -0.20 | 0.10 | 1.40 | 0.78 | 24.95 | +0.25 -0.40 | 1.30 | 2.2 | 37.8 | 35.9 | 28.4 | 10.3 | ||

| MSH-28 | 28 | 1.102 | 26.40 | 0.10 | 1.40 | 0.80 | 25.80 | 1.30 | 2.3 | 38.8 | 36.9 | 28.4 | 11.0 | ||||

| MSH-30 | 30 | 1.181 | 28.35 | 0.15 | 1.40 | 0.83 | 27.90 | 1.30 | 2.5 | 40.8 | 38.8 | 31.6 | 12.3 | ||||

| MSH-32 | 32 | 1.260 | 30.20 | 0.15 | 1.40 | 0.30 | 29.60 | 1.30 | 2.8 | 42.8 | 40.7 | 33.6 | 14.1 | ||||

| MSH-34 | 34 | 1.339 | 32.00 | 0.15 | 1.40 | 1.00 | 31.40 | 1.30 | 3.1 | 44.9 | 42.5 | 36.0 | 16.7 | ||||

| MSH-35 | 35 | 1.378 | 32.90 | 0.15 | 1.40 | 1 05 | 32.30 | 1.30 | 3.3 | 45.9 | 43.4 | 37.0 | 18.1 | ||||

| MSH-36 | 36 | 1.417 | 33 35 | 0.15 | 1 40 | 1.06 | 33 25 | 1.30 | 3.6 | 48.6 | 46.1 | 38 0 | 18 9 | ||||

| MSH-3S | 38 | 1.496 | 35.80 | -0.30 | 0.15 | 1.40 | 1.10 | 35.20 | 1.30 | 4.0 | 50.6 | 48.0 | 40.0 | 20.5 | |||

| MSH-40 | 40 | 1.575 | 37.70 | 0.15 | 1.75 | + 0.20 | 1.15 | 36.75 | +0.35 -0.50 | 1.60 | ±0.08 | 5.6 | 54.0 | 51.3 | 52.0 | 22.6 | |

| MSH-42 | 42 | 1.654 | 39.60 | 0.15 | 1.75 | 1.20 | 38.80 | 1.60 | 6.3 | 56.0 | 53.2 | 54.0 | 24.8 | ||||

| MSH-43 | 43 | 1.683 | 40.50 | 0.15 | 1.75 | 1.25 | 39.65 | 1.60 | 6.7 | 57.0 | 54.0 | 55.0 | 26.4 | ||||

| MSH-45 | 45 | 1.772 | 42.40 | 0.15 | 1.75 | 1.30 | 41.60 | 1.60 | 7.0 | 59.0 | 55.9 | 58.0 | 28.8 | ||||

| MSH-46 | 46 | 1.611 | 43.30 | 0.15 | 1.75 | 1.35 | 42.55 | 1.60 | 7.3 | 60.0 | 56.8 | 59.0 | 30.4 | ||||

| MSH-48 | 48 | 1.890 | 45.20 | 0.15 | 1.75 | 1.40 | 44.40 | 1.60 | 7.7 | 62.4 | 59.1 | 62.0 | 33.0 | ||||

| MSH-50 | 50 | 1.969 | 47.20 | 0.15 | 1.75 | 1.40 | 46.20 | 1.60 | 8.2 | 64.4 | 61.1 | 64.0 | 35.0 | ||||

| RING NO. | LUG HEIGHT | MAXIMUM SECTION | MINIMUM SECTION | HOLE DIAMETER | GAGING DIA. | ALLOWABLE CORNER RADII & CHAMFERS | MAX. LOAD W R max or Ch max (kN) | EDGE MARGIN | R.P.M. LIMITS Standard Material | |

| H nom | S max/Ref. | S m in/Ref. | R min | Gd | R max | Ch max | P’r | Y | RPM | |

| MSH-4* | 1.35 | 0.65 | 0.40 | 0.6 | 4.90 | 0.35 | 0.25 | 0.2 | 0.3 | 70000 |

| MSH-5* | 1.40 | 0.65 | 0.40 | 0.6 | 5.85 | 0.35 | 0.25 | 0.5 | 0.4 | 70000 |

| MSH-6* | 1.40 | 0.75 | 0.50 | 0.6 | 6.95 | 0.35 | 0.25 | 0.5 | 0.5 | 70000 |

| MSH-7 | 2.05 | 0.90 | 0.60 | 1.0 | 8.05 | 0.45 | 0.3 | 2.1 | 0.6 | 60000 |

| MSH-6 | 2.20 | 1.00 | 0.65 | 1.0 | 9.15 | 0.5 | 0.35 | 2.1 | 0.8 | 55000 |

| MSH-9 | 2.20 | 1.15 | 0.75 | 1.0 | 10.35 | 0.6 | 0.35 | 2.1 | 0.8 | 48000 |

| MSH-10 | 2.20 | 1.30 | 0.80 | 1.0 | 11.50 | 0.7 | 0.4 | 2.1 | 0.9 | 42000 |

| MSH-11 | 2.20 | 1.40 | 0.85 | 1.0 | 12.50 | 0.75 | 0.45 | 2.1 | 1.0 | 38000 |

| MSH-12 | 2.20 | 1.50 | 0.90 | 1.0 | 13.30 | 0.8 | 0.45 | 2.1 | 1.0 | 34000 |

| MSH-13 | 2.80 | 1.60 | 0.95 | 1.2 | 15.05 | 0.8 | 0.5 | 4.0 | 1.0 | 31000 |

| MSH-14 | 2 SO | 1.70 | 1.00 | 1.2 | 15.50 | 0.9 | 0.5 | 4.0 | 1.2 | 28000 |

| MSH-15 | 2.30 | 1.30 | 1.05 | 1.2 | 17.20 | 1.0 | 0.6 | 4.0 | 1.3 | 27000 |

| MSH-16 | 2.SO | 2.05 | 1.15 | 1.2 | 18.35 | 1.1 | 0.6 | 4.0 | 1.4 | 25000 |

| MSH-17 | 2.SO | 2.10 | 1.15 | 1.2 | 19.35 | 1.1 | 0.6 | 4.0 | 1.4 | 24000 |

| MSH-18 | 3.45 | 2.25 | 1.25 | 1.3 | 20.60 | 1.2 | 0.7 | 6.0 | 1.5 | 23000 |

| MSH-19 | 3.45 | 2.35 | 1.30 | 1.3 | 21.70 | 1.2 | 0.7 | 6.0 | 1.6 | 21500 |

| MSH-20 | 3.45 | 2.40 | 1.35 | 1.3 | 22.65 | 1.2 | 0.7 | 6.0 | 1.7 | 20000 |

| MSH-21 | 3.45 | 2.50 | 1.40 | 1.3 | 23.80 | 1.3 | 0.7 | 6.0 | 1.8 | 19000 |

| MSH-22 | 3.45 | 2.70 | 1.50 | 1.3 | 24.90 | 1.3 | 0.8 | 6.0 | 1.9 | 18500 |

| MSH-23 | 3.45 | 2.80 | 1.60 | 1.3 | 26.00 | 1.3 | 0.8 | 6.0 | 2.0 | 18000 |

| MSH-24 | 4.20 | 2.90 | 1.60 | 1.9 | 27.15 | 1.4 | 0.8 | 6.0 | 2.1 | 17500 |

| MSH-25 | 4.20 | 2.90 | 1.70 | 1.9 | 28.10 | 1.4 | 0.8 | 6.0 | 2.3 | 17000 |

| MSH-26 | 4.20 | 3.00 | 1.70 | 1.9 | 29.25 | 1.5 | 0.9 | 6.0 | 2.3 | 16500 |

| MSH-27 | 4.60 | 3.10 | 1.80 | 1.9 | 30.35 | 1.5 | 0.9 | 8.6 | 2.3 | 16300 |

| MSH-28 | 4 SO | 3.20 | 1.80 | 1.9 | 31.45 | 1.6 | 1.0 | 8.6 | 2.4 | 15800 |

| MSH-30 | 4.SO | 3.30 | 1.80 | 1.9 | 33.50 | 1.6 | 1.0 | 8.6 | 2.5 | 15000 |

| MSH-32 | 4.50 | 3.60 | 1.90 | 1.9 | 35.90 | 1.7 | 1.0 | 8.6 | 2.7 | 14800 |

| MSH-34 | 4.50 | 3.30 | 2.00 | 1.9 | 37.90 | 1.7 | 1.1 | 8.6 | 3.0 | 14000 |

| MSH-35 | 4.50 | 3.90 | 2.10 | 1.9 | 39.00 | 1.8 | 1.1 | 8.6 | 3.1 | 13500 |

| MSH-36 | 5.40 | 4.10 | 2.20 | 1.9 | 40.20 | 1.9 | 1.2 | 8.6 | 3.2 | 13300 |

| MSH-3S | 5.40 | 4.30 | 2.30 | 3.1 | 42.50 | 2.0 | 1.2 | 8.6 | 3.3 | 12700 |

| MSH-40 | 6.00 | 4.40 | 2.30 | 3.1 | 44.50 | 2.1 | 1.2 | 13.2 | 3.4 | 12000 |

| MSH-42 | e.oo | 4.60 | 2.40 | 3.1 | 40.90 | 2.2 | 1.3 | 13.2 | 3.6 | 11000 |

| MSH-43 | 6.00 | 4.70 | 2.50 | 3.1 | 47.90 | 2.3 | 1.4 | 13.2 | 3.8 | 10800 |

| MSH-45 | 6.00 | 4.30 | 2.60 | 3.1 | 50.00 | 2.3 | 1.4 | 13.2 | 3.S | 10000 |

| MSH-46 | 6.00 | 4.90 | 2.60 | 3.1 | 50.90 | 2.4 | 1.4 | 13.2 | 4.0 | 9500 |

| MSH-48 | 6.20 | 5.00 | 2.60 | 3.1 | 53.00 | 2.4 | 1.4 | 13.2 | 4.2 | 8800 |

| MSH-50 | 6.20 | 5.10 | 2.70 | 3.1 | 55.20 | 2.4 | 1.4 | 13.2 | 4.2 | 8000 |

| RING NO. | SHAFT DIAMETER | GROOVE SIZE | RING SIZE & WEIGHT | CLEARANCE DIA. | i THRUST LD (kN) Sqr. corner abutment | ||||||||||||

| DIAMETER | WIDTH | DEPTH | FREE DIAMETER | THICKNESS *** | Wt. Per 1000 pcs. | Ex- panded over Shaft | Re- leased in Groove | ||||||||||

| Ring (Safety Factor of 4) | Groove (Safety Factor of 2) | ||||||||||||||||

| Ds mm | Ds INCH | ||||||||||||||||

| Dg | tol | F.I.M.** | W | tol | d | Df | Ю1 | T | tol | kg | LI | L2 | Pr | PS | |||

| MSH-54 | 54 | 2.126 | 51.00 | -0.30 | 0.15 | 2.15 | + 0.2C | 1.50 | 49.90 | +0.35 -0.65 | 2.00 | ±0.08 | 11.8 | 69.6 | 66.1 | 87.0 | 40.0 |

| MSH-55 | 55 | 2.165 | 51.80 | 0.15 | 2.15 | 1.60 | 50.60 | 2.00 | 11.9 | 70.6 | 66.9 | 89.0 | 44.0 | ||||

| MSH-57 | 57 | 2.244 | 53.80 | -0.40 | 0.20 | 2.15 | 1.60 | 52.90 | 2.00 | 12.5 | 72.6 | 6B.9 | 91.0 | 45.0 | |||

| MSH-5S | 58 | 2.283 | 54.70 | 0.20 | 2.15 | 1.65 | 53.60 | 2.00 | 12.6 | 73.6 | 69.8 | 93.0 | 46.0 | ||||

| MSH-60 | 60 | 2.362 | 56.70 | 0.20 | 2.15 | 1.65 | 55.80 | 2.00 | 13.2 | 75.6 | 71.8 | 97.0 | 49.0 | ||||

| MSH-62 | 62 | 2.441 | 58.60 | 0.20 | 2.15 | 1.70 | 57.30 | 2.00 | 13.4 | 77.6 | 73.6 | 100.0 | 52.0 | ||||

| MSH-65 | 65 | 2.559 | 61.60 | 0.20 | 2 15 | 1.70 | 60.40 | +0.50 -0.75 | 2.00 | 15.4 | 30.6 | 76.6 | 105.0 | 54.0 | |||

| MSH-68 | 6S | 2.677 | 64.50 | 0.20 | 2 15 | 1.75 | 63.10 | 2.00 | 16.3 | 33.6 | 79.5 | 110.0 | 58.0 | ||||

| MSH-70 | 70 | 2.756 | 66.40 | 0.20 | 2.55 | 1.80 | 64.60 | 2.40 | 19.3 | 88.1 | 83.9 | 136.0 | 62.0 | ||||

| MSH-72 | 72 | 2.835 | 68.30 | 0.20 | 2.55 | 1.85 | 66.60 | 2.40 | 20.6 | 90.1 | 85.8 | 140.0 | 65.0 | ||||

| MSH-75 | 75 | 2.953 | 71.20 | 0.20 | 2.55 | 1.90 | 69.00 | 2.40 | 22.6 | 93.1 | 83.7 | 147.0 | 69.0 | ||||

| MSH-78 | 73 | 3.071 | 74.00 | 0.20 | 2.55 | 2.00 | 72.00 | 2.40 | 21.5 | 95.4 | 92.1 | 151.0 | 76.0 | ||||

| MSH-80 | 8O | 3.150 | 75.90 | 0.20 | 2.55 | 2.05 | 74.20 | 2.40 | 26.8 | 97.9 | 93.1 | 155.0 | 80.0 | ||||

| MSH-32 | 82 | 3.228 | 77.80 | 0.20 | 2.55 | 2.10 | 76.40 | 2.40 | 28.1 | 100.0 | 95.1 | 159.0 | 84.0 | ||||

| MSH-85 | 85 | 3.346 | 30.60 | 0.20 | 2.55 | 2.20 | 73.60 | 2.40 | 29.0 | 103.0 | 97.9 | 165.0 | 91.0 | ||||

| MSH-88 | 88 | 3.464 | 33.50 | 0.20 | 2.95 | 2.25 | 81.40 | 2.80 | 32.2 | 107.0 | 100.8 | 199.0 | 97.0 | ||||

| MSH-90 | 90 | 3.543 | 35.40 | 0.20 | 2.95 | 2.30 | 83.20 | 2.80 | 33.1 | 109.0 | 103.6 | 204.0 | 101.0 | ||||

| MSH-95 | 95 | 3.740 | 90.20 | 0.20 | 2.95 | 2.40 | 88.10 | 2.80 | 37.6 | 114.0 | 108.6 | 215.0 | 112.0 | ||||

| MSH-100 | 100 | 3.852 | 95.20 | 0.20 | 2.95 | 2.42 | 92.50 | 2.80 | 43.1 | 119.5 | 113.7 | 227.0 | 123.0 | ||||

| RING NO. | LUG HEIGHT | MAXIMUM SECTION | MINIMUM SECTION | HOLE DIAMETER | GAGING DIA. | ALLOWABLE CORNER RADII & CHAMFERS | MAX. LOAD w/ R max or Ch max (kN) | EDGE MARGIN | R.P.M. LIMITS Standard Material | |

| H nom | S max/Ref. | S min/Ref. | Rmin | Gd | Rmax | Ch max | P'r | Y | RPM | |

| MSH-54 | 6.80 | 5.40 | 2.90 | 3.1 | 59.50 | 2.5 | 1.5 | 22.0 | 4.5 | 7500 |

| MSH-55 | 6.80 | 5.40 | 2.90 | 3.1 | 60.40 | 2.5 | 1.5 | 22.0 | 4.8 | 7400 |

| MSH-57 | 6.80 | 5.60 | 3.00 | 3.1 | 62.70 | 2.6 | 1.5 | 22.0 | 4.8 | 7200 |

| MSH-58 | 6.80 | 5.60 | 3.00 | 3.1 | 63.60 | 2.6 | 1.6 | 22.0 | 4.9 | 7100 |

| MSH-60 | 6.80 | 5.70 | 3.00 | 3.1 | 65.80 | 2.6 | 1.6 | 22.0 | 4.9 | 7000 |

| MSH-62 | 6.80 | 5.80 | 3.00 | 3.1 | 67.90 | 2.7 | 1.6 | 22.0 | 5.1 | 6900 |

| MSH-55 | 6.80 | 6.00 | 3.10 | 3.1 | 71.20 | 2.8 | 1.7 | 22.0 | 5.1 | 6700 |

| MSH-60 | 6.80 | 6.20 | 3.30 | 3.1 | 74.50 | 2.9 | 1.7 | 22.0 | 5.3 | 6500 |

| MSH-70 | 7.80 | 6.30 | 3.30 | 3.1 | 76.40 | 2.9 | 1.7 | 32.0 | 5.4 | 6400 |

| MSH-72 | 7.80 | 6.40 | 3.30 | 3.1 | 78.50 | 2.9 | 1.7 | 32.0 | 5.5 | 6200 |

| MSH-75 | 7.80 | 6.60 | 3.40 | 3.1 | 81.70 | 3.0 | 1.8 | 32.0 | 5.7 | 5900 |

| MSH-7B | 7.80 | 6.60 | 3.40 | 3.1 | 84.60 | 3.0 | 1.8 | 32.0 | 6 | 5600 |

| MSH-80 | 7.80 | 7.00 | 3.60 | 3.1 | 87.00 | 3.1 | 1.9 | 32.0 | 6.1 | 5400 |

| MSH-62 | 7.80 | 7.10 | 3.70 | 3.1 | 89.00 | 3.2 | 1.9 | 32.0 | 6.3 | 5200 |

| MSH-85 | 7.80 | 7.30 | 3.80 | 3.1 | 92.10 | 3.2 | 1.9 | 32.0 | 6.6 | 5000 |

| MSH-88 | S.40 | 7.50 | 3.90 | 3.1 | 95.10 | 3.2 | 1.9 | 47.0 | 6.7 | 4800 |

| MSH-90 | 0.40 | 7.50 | 3.90 | 3.1 | 97.10 | 3.2 | 1.9 | 47.0 | 6.9 | 4500 |

| MSH-95 | 8.40 | 7.90 | 4.10 | 3.1 | 102.70 | 3.4 | 2.1 | 47.0 | 7.2 | 4350 |

| MSH-100 | 8.70 | 8.00 | 4.10 | 3.1 | 108.00 | 3.5 | 2.1 | 47.0 | 7.5 | 4150 |

HARDNESS RANGES: STAINLESS STEEL RINGS (PH 15-7M0)

| RING TYPE | SIZE RANGE | SCALE | ROCKWELL HARDNESS |

| MSH | 7-21 | 30N | 63-69.5 |

| 22-100 | С | 44-51 |

HARDNESS RANGES: CARBON STEEL RINGS (SAE 1060-1090)

| RING TYPE | SIZE RANGE | SCALE | ROCKWELL HARDNESS |

| MSH | 7-12 | 30N | 69.5-73 |

| 13-21 | 30 N | 67.5-71 | |

| 22-26 | С | 49-53 | |

| 27-85 | С | 48-52 | |

| 88-100 | С | 47-51 |